Product Enquiry

Enter your details below to enquire about this product with Sheet Metal Tooling Tech

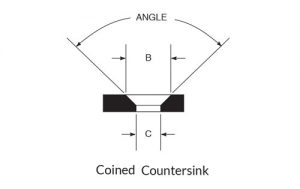

Coin

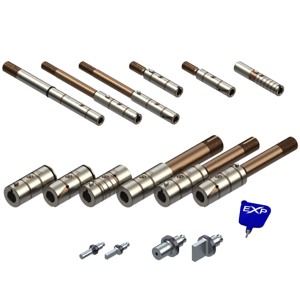

Coining operations (also known as counter sinking) on the punch press eliminate the costly and time consuming secondary operation of drilling countersinks. The interchangeable tip design allows you to change the size of your coin easily and inexpensively while the replaceable insert design also lowers tooling costs and inventory.

Product Enquiry

Enter your details below to enquire about this product with Sheet Metal Tooling Tech

-

WHY TAKE EXTRA STEPS?

The old way to make a countersink was a three-step process: punch the hole, drill the sink, deburr. Three-step processes like this cost unnecessary time and money.

A forming countersink tool for the punch press is made to your exact specifications and produces a clean countersink in seconds. It eliminates the labor-intensive drill and deburr operations. This cuts your production time by 50% or more.

SEE HOW TO SINK IN ONE STEP

Wilson Tool countersinking tool punches a countersink without the need for a secondary operation. Countersinking is done quickly and precisely in one stroke of the punch.